Format: PDF

Pages: 3,100+

Compatible with: Windows/Mac/Tablet

File size: 230mb

Includes CHASSIS WORKSHOP MANUAL 00ELT0104, ENGINE WORKSHOP MANUAL 00ELT0103 AND ELECTRICAL WORKSHOP MANUAL 00ELT0105

Covers: Mitsubishi FUSO Canter Euro6 FE, FG Truck (Europe) Service & Repair

- FE and FG series

- Mits/Iveco 4P10-T2, 4P10-T4 or 4P10-T6 engine

- Euro 6 OBD only

- See full model list at bottom of page

Chassis Workshop Manual Topics:

GENERAL INFORMATION

SPECIFICATIONS

MAINTENANCE

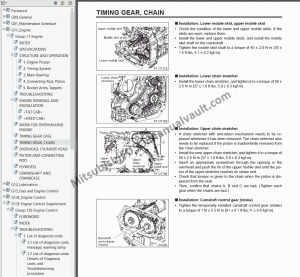

ENGINE

LUBRICATION

FUEL AND ENGINE CONTROL

COMMON RAIL SYSTEM

COOLING

INTAKE AND EXAUST

EMISSION CONTROL

BlueTec SYSTEM

GROUP INDEX

CLUTCH

GEARBOX <M038: DUONIC>

GEARBOX <M038>

REAR SUSPENSION

HANDBRAKE

STEERING <RIGID LEAF SUSPENSION>

ABS/ESP/ASR

BRAKE

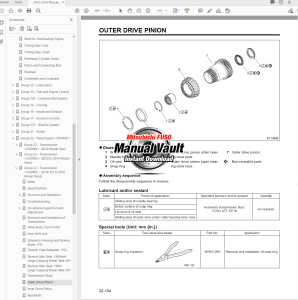

PROPELLER SHAFT

FRONT AXLE <RIGID LEAF SUSPENSION (FE)>

REAR AXLE

WHEEL, TYRE

FRONT SUSPENSION <RIGID LEAF TYPE>

TRANSFER

FRONT AXLE <RIGID LEAF SUSPENSION (FG)>

FRONT AXLE <INDEPENDENT SUSPENSION>

FRONT SUSPENSION <INDEPENDENT TYPE>

STEERING <INDEPENDENT SUSPENSION>

ENGINE STARTING, STOPPING AND PREHEATING CIRCUIT

LIGHTING CIRCUIT

METER CIRCUIT

INDICATOR AND WARNING LIGHT CIRCUIT

CAB SIDE ELECTRICAL CIRCUIT

BUMPER, FRAME

CAB MOUNTING, TILT

DOOR

EXTERIOR

INTERIOR

Electrical Workshop Manual Topics:

GENERAL

SPECIFICATIONS

STRUCTURE AND OPERATION

TROUBLESHOOTING

POWER, CHARGE AND EARTH CIRCUIT

ENGINE STARTING, STOPPING AND PREHEATING CIRCUIT

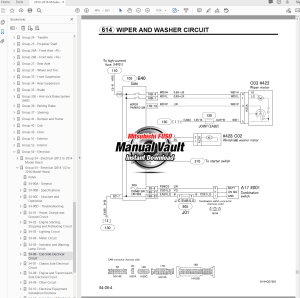

LIGHTING CIRCUIT

METER CIRCUIT

INDICATOR AND WARNING LAMP CIRCUIT

CAB SIDE ELECTRICAL CIRCUIT

CHASSIS SIDE ELECTRICAL CIRCUIT

ENGINE AND GEARBOX SIDE ELECTRICAL CIRCUIT

OTHER CIRCUIT

ELECTRICAL EQUIPMENT INSTALLATION POSITIONS

INSPECTION OF ELECTRICAL EQUIPMENT

STARTER AND ALTERNATOR

ON-VEHICLE INSPECTION AND ADJUSTMENT

CONNECTOR CONFIGURATION CHART

IDLING STOP AND START SYSTEM

LDWS (LANE DEPARTURE WARNING SYSTEM)

IMMOBILISER

METER CLUSTER

SIGNAL DETECTED AND ACTUATION MODULES

Engine Workshop Manual Topics:

GENERAL INFORMATION

4P10T2, 4P10T4, 4P10T6 ENGINE (SPECIFICATIONS, SERVICE, ETC)

LUBRICATION

FUEL AND ENGINE CONTROL

COMMON RAIL SYSTEM

COOLING SYSTEM

INTAKE AND EXHAUST

EMISSION CONTROL

BlueTec SYSTEM

Full Model List:

- FEA01BL4SEU2

- FEA01BL4SEU3

- FEA01CL4SEU2

- FEA01CL4SEU3

- FEA51BL4SEU3

- FEA51CL4SEU3

- FEA51EL4SEU3

- FEB01BL4SEU2

- FEB01BL4SEU3

- FEB01CL4SEU2

- FEB01CL4SEU3

- FEB01EL4SEU2

- FEB01EL4SEU3

- FEB01EL4WEU2

- FEB01GL4SEU2

- FEB01GL4SEU3

- FEB71CL4SEU3

- FEB71CL4SEU4

- FEB71EL4SEU3

- FEB71EL4SEU4

- FEB71GL4SEU3

- FEB71GL4SEU4

- FEB71GL4WEU3

- FEB71GL4WEU4

- FEC71HL4SEU3

- FEC71HL4SEU4

- FEC71KL4SEU4

- FEB01BR4SEU2

- FEB01CR4SEU2

- FEB01ER4SEU2

- FEB01ER4WEU2

- FEB01GR4SEU2

- FEB71CR4SEU3

- FEB71ER4SEU3

- FEB71GR4SEU3

- FEB71GR4WEU3

- FEC71HR4SEU3

- FEC71KR4SEU3

- FEA01BL3SEU2

- FEA01BL3SEU3

- FEA01CL3SEU2

- FEA01CL3SEU3

- FEB01BL3SEU2

- FEB01BL3SEU3

- FEB01CL3SEU2

- FEB01CL3SEU3

- FEB01EL3SEU2

- FEB01EL3SEU3

- FEB01EL3WEU3

- FEB01GL3SEU2

- FEB01GL3SEU3

- FEB71CL3SEU3

- FEB71EL3SEU3

- FEB71EL3SEU4

- FEB71GL3SEU3

- FEB71GL3SEU4

- FEB71GL3WEU4

- FECX1EL3SEU4

- FECX1GL3SEU4

- FECX1HL3SEU4

- FECX1KL3SEU4

- FEC71HL3SEU3

- FEC71HL3SEU4

- FEC71KL3SEU4

- FEC71KL3WEU4

- FEB01BR3SEU2

- FEB01BR3SEU3

- FEB01CR3SEU2

- FEB01CR3SEU3

- FEB01ER3SEU2

- FEB01ER3SEU3

- FEB01ER3WEU3

- FEB01GR3SEU2

- FEB01GR3SEU3

- FEB71CR3SEU3

- FEB71ER3SEU3

- FEB71ER3SEU4

- FEB71GR3SEU3

- FEB71GR3SEU4

- FECX1ER3SEU4

- FECX1GR3SEU4

- FECX1HR3SEU4

- FECX1KR3SEU4

- FEC71HR3SEU3

- FEC71HR3SEU4

- FEC71KR3SEU3

- FEC71KR3SEU4

- FEC71KR3WEU4

- FGB71EL6SEU4

- FGB71EL6WEU4

- FGB71GL6SEU4

- FGB71GL6WEU4

- FGB71ER6SEU4

- FGB71ER6WEU4

- FGB71GR6SEU4