Pages: 1,536

Compatible with: Windows/Mac/Tablet/Phone

Covers: 1992, 1993, 1994, 1995 Mitsubishi FUSO FH Series Truck (U.S. model) Service & Repair

- FH100 with 6D31-T2 engine

Manual Part Number: TWME9106 plus model year changes

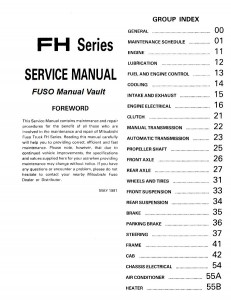

Topics List:

Group 00 – General

Group 00 – General (Supplement)

Group 00 – General (’95 Minor Change)

Group 00 – General (’94 Minor Change)

Group 00 – General (’93 Minor Change)

Group 00 – General

Table of Contents

1. External Views

2. Major Specifications

3. Power Train Table

4. Equipment Model Notation

5. Performance Curves

5.1 Operation Performance Curves

5.2 Engine Performance Curves

6. Servicing Precautions

7. Standard Bolts and Nuts Tightening Torque Table

8. Towing Precautions

9. Chassis and Engine Numbers

10. Vehicle Identification Number

Group 01 – Maintenance Schedule

Table of Contents

1. How to Read the Maintenance Schedule Tables

2. Maintenance Schedule Tables

3. Maintenance Operations

3.1 Replacement of the Engine Oil Filter Element

3.2 Replacement of the Fuel Filter Element

3.3 Inspection of Air Dryer

3.4 Cleaning of the Fuel Feed Pump Gauze Filter

3.5 Bleeding Air from the Fuel Line

3.6 Water Separator Condensation Drain

3.7 Adjusting V-Belt Tension

3.8 Cleaning and Replacement of the Air Cleaner Element

3.9 Inspecting the Clutch Pedal <Vehicles with Manual Transmission>

3.10 The Tires

3.10.1 Air Pressure

3.10.2 Removing Tires

3.10.3 Tire Mounting

3.10.4 Checking the Wheel Nuts for Looseness

3.10.5 Tire Rotation

3.11 Adjusting the Clearance of the Wheel Brake Shoe

3.12 Adjusting the Clearance of the Parking Brake Shoe

3.13 The Battery

3.14 Fuses

4. Lubrication

4.1 Engine Oil

4.2 Gear Oil for Manual Transmission

4.3 Automatic Transmission Fluid and Oil Filters for Automatic Transmission

4.4 Rear Axle Gear Oil

4.5 Power Steering Fluid

4.6 Brake Fluid

4.6.1 Brake Fluid Tank

4.6.2 Clutch Fluid Tank

4.7 Greasing the Various Areas of the Chassis

Group 11 – Engine

Table of Contents

1. Troubleshooting

2. Engine Removal and Installation (Manual Transmission Vehicles)

2.1 Service Standards

2.1.1 Tightening Torque Table

2.2 Removal of Engine and Transmission

2.2.1 Preparation for Removal

2.2.2 Removal of Harness

2.2.3 Removal of Air Compressor Hoses, Actuator and Tube Assembly

2.2.4 Removal of Parts Around the Engine

2.2.5 Removal of Engine Parts

2.2.6 Removal of Transmission Parts

2.2.7 Removal of Transmission

2.2.8 Removing the Engine from the Vehicle

2.3 Installation of the Engine and Transmission

2.3.1 Installation of Engine

2.3.2 Installation of Transmission

2.3.3 Installation of Transmission Parts

2.3.4 Installation of Engine Parts

2.3.5 Installation of Parts Around the Engine

2.3.6 Installation of Air Compressor Hoses, Actuator and Tube Assembly

2.3.7 Installation of Harness

2.4 Adjustment After Installation

2.4.1 Preparation for Adjustment

2.4.2 Adjustment

3. Engine Removal and Installation (Automatic Transmission Vehicles)

3.1 Service Standards

3.1.1 Tightening Torque Table

3.2 Removal of Engine and Transmission

3.2.1 Preparation for Removal

3.2.2 Removal of Harness

3.2.3 Removal of Air Compressor Hose

3.2.4 Removal of Parts Around the Engine

3.2.5 Removal of Engine Parts

3.2.6 Removal of Transmission Parts

3.2.7 Removal of Transmission

3.2.8 Removing the Engine from the Vehicle

3.3 Installation of the Engine and Transmission

3.3.1 Installation of the Engine

3.3.2 Installation of Transmission

3.3.3 Installation of Transmission Parts

3.3.4 Installation of Engine Parts

3.3.5 Installation of Parts Around the Engine

3.3.6 Installation of Air Compressor Hose

3.3.7 Installation of Harnesses

3.4 Adjustment After Installation

3.4.1 Preparation for Adjustment

3.4.2 Adjustment

4. Engine Assembly

4.1 Specifications

4.2 Service Standards

4.2.1 Service Standards Table

4.2.2 Tightening Torque Table

4.2.3 Special Tools Table

4.3 Inspection and Adjustment of Valve Clearance

4.4 Measurement of Compression Pressure

4.5 Inspection of Oil Pressure

4.6 Inspection and Adjustment of Fuel Injection Start Timing

4.7 Bleeding the Fuel System

4.8 Inspection and Adjustment of V-Belt Tension

4.9 Measurement of Turbocharger Boost Pressure

5. Cylinder Head and Valve Mechanism

5.1 Service Standards

5.1.1 Service Standards Table

5.1.2 Tightening Torque Table

5.1.3 Special Tools Table

5.2 General Description

5.2.1 Cylinder Head

5.2.2 Valve Mechanism

5.3 Removal

5.4 Disassembly

5.4.1 Rocker and Bracket Assembly

5.4.2 Cylinder Head Assembly

5.5 Inspection

5.6 Reassembly

5.6.1 Cylinder Head Assembly

5.6.2 Rocker and Bracket Assembly

5.7 Installation

6. Flywheel and Flywheel Housing (Manual Transmission Vehicles)

6.1 Service Standards

6.1.1 Service Standards Table

6.1.2 Tightening Torque Table

6.1.3 Special Tools Table

6.1.4 Sealant Table

6.2 General Description

6.3 Disassembly

6.4 Inspection

6.5 Reassembly

7. Flywheel and Flywheel Housing (Automatic Transmission Vehicles)

7.1 Service Standards

7.1.1 Tightening Torque Table

7.1.2 Special Tools Table

7.1.3 Sealant Table

7.2 General Description

7.3 Disassembly

7.4 Inspection

7.5 Reassembly

8. Timing Gear and Camshaft

8.1 Service Standards

8.1.1 Service Standards Table

8.1.2 Tightening Torque Table

8.1.3 Lubricant Table

8.1.4 Sealant Table

8.1.5 Special Tools Table

8.2 General Description

8.3 Disassembly

8.4 Inspection

8.5 Reassembly

9. Crankcase and Main Moving Parts

9.1 Service Standards

9.1.1 Service Standards Table

9.1.2 Tightening Torque Table

9.1.3 Sealant Table

9.1.4 Special Tools Table

9.2 General Description

9.2.1 Crankshaft

9.2.2 Connecting Rod

9.2.3 Piston

9.3 Disassembly

9.4 Inspection

9.5 Reassembly

Group 12 – Lubrication

Table of Contents

1. Troubleshooting

2. Lubrication System

2.1 Specifications

2.2 General Description

2.2.1 System Outline

2.2.2 Lubrication of Main Moving Parts

2.2.3 Camshaft Lubrication

2.2.4 Valve Mechanism Lubrication

2.2.5 Timing Gear Lubrication

2.2.6 Turbocharger Lubrication

2.2.7 Injection Pump Assembly Lubrication

2.2.8 Air Compressor Lubrication

2.3 Oil Pressure Check

3. Oil Pan and Oil Strainer

3.1 Service Standards

3.1.1 Tightening Torque Table

3.1.2 Sealant Table

3.2 General Description

3.3 Removal

3.4 Installation

3.5 Post-Installation Inspection

4. Oil Pump

4.1 Service Standards

4.1.1 Service Standards Table

4.2 General Description

4.3 Removal

4.4 Disassembly and Inspection

4.5 Reassembly

4.6 Installation

5. Oil Cooler and Oil Filter

5.1 Service Standards

5.1.1 Service Standards Table

5.1.2 Tightening Torque Table

5.1.3 Special Tools Table

5.2 General Description

5.3 Removal

5.4 Disassembly and Inspection

5.5 Reassembly

5.6 Installation

Group 13 – Fuel and Engine Control

Table of Contents

1. Troubleshooting

2. Fuel System

2.1 General Description

2.2 Removal and Installation of the Fuel Hoses

3. Prestroke Control Type Injection Pump System

3.1 Specifications

3.2 Service Standards

3.2.1 Service Standards Table

3.2.2 Tightening Torque Table

3.2.3 Special Tools Table

3.3 General Description

3.3.1 Prestroke Control Type Injection Pump System

3.3.2 Control Unit

3.3.3 Sensors

3.3.4 Injection Pump Proper

3.3.5 Governor

3.3.6 Feed Pump

3.3.7 Coupling

3.4 Service Procedure

3.4.1 Inspection of System

3.4.2 Removal of Injection Pump Assembly

3.4.3 Installation of Injection Pump Assembly

3.4.4 Adjustments After Installation of Injection Pump

3.4.5 Bleeding Air from the Fuel System

3.4.6 Adjustment of Fuel Injection Timing

3.4.7 Adjustment of No-Load Minimum and Maximum Speeds

3.4.8 Operation Check of the Engine Stop Cable

4. Injection Nozzles

4.1 Specifications

4.2 Service Standards

4.2.1 Service Standards Table

4.2.2 Tightening Torque Table

4.3 General Description

4.4 Removal

4.5 Disassembly

4.6 Inspection and Cleaning

4.7 Reassembly

4.8 Test and Adjustment

4.9 Installation

5. Fuel Filter

5.1 Specifications

5.2 Service Standards

5.2.1 Tightening Torque Table

5.2.2 Special Tools Table

5.3 General Description

5.4 Removal and Inspection

5.5 Installation

6. Water Separator

6.1 Specifications

6.2 Service Standards

6.3 General Description

6.4 Removal

6.5 Disassembly and Inspection

6.6 Reassembly

6.7 Installation

6.8 Draining Water

7. Fuel Tank

7.1 Specifications

7.2 Service Standards

7.3 General Description

7.4 Removal

7.5 Inspection

7.6 Installation

8. Engine Control System

8.1 Specifications

8.2 Service Standards

8.3 General Description

8.4 Removal

8.4.1 Disconnecting the Accelerator Control Cable and Engine Stop Cable

8.4.2 Removal of the Throttle Cable

8.4.3 Removal of the Accelerator Pedal and Accelerator Lever Assembly

8.5 Inspection

8.6 Installation

8.6.1 Installation of Accelerator Lever Assembly and Accelerator Pedal

8.6.2 Installation of Throttle Cable

8.6.3 Installation of Accelerator Control Cable and Engine Stop Cable

8.7 Adjustment After Installation

8.7.1 Adjustment of the Accelerator Pedal Stopper

8.7.2 Operation Check of the Engine Stop Cable

8.7.3 Adjustment of the Accelerator Switch (Exhaust Brake Microswitch)

Group 14 – Cooling

Table of Contents

1. Troubleshooting

2. Cooling System

2.1 Specifications

2.2 General Description

2.3 Removal

2.3.1 Preparation for Removal

2.3.2 Radiator and Reservoir Tank Removal

2.3.3 Cooling Fan and Auto-Cool Fan Coupling Removal

2.3.4 Water Pump Removal

2.3.5 Thermostat Removal

2.4 Installation

2.4.1 Thermostat Installation

2.4.2 Water Pump Installation

2.4.3 Cooling Fan and Auto-Cool Fan Coupling Installation

2.4.4 Radiator and Reservoir Tank Installation

2.4.5 Operations After Installation

3. Cooling Fan and Auto-Cool Fan Coupling

3.1 General Description

3.1.1 Cooling Fan

3.1.2 Auto-Cool Fan Coupling

3.2 Auto-Cool Fan Coupling Inspection

4. Thermostat

4.1 Service Standards

4.1.1 Service Standards Table

4.2 General Description

4.3 Inspection

5. Radiator

5.1 Service Standards

5.2 General Description

5.2.1 Radiator

5.2.2 Pressure Cap

5.2.3 Radiator Shroud

5.2.4 Reservoir Tank

5.3 Inspection and Cleaning

5.3.1 Radiator Cleaning

5.3.2 Radiator Inspection

5.3.3 Pressure Cap Inspection

5.3.4 Radiator (Cooling System) Cleaning

5.3.5 Gas Leak Test

5.3.6 Cooling System Air Bleeding

Group 15 – Intake and Exhaust

Table of Contents

1. Troubleshooting

2. Intake System

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.3 General Description

2.4 Removal

2.5 Air Cleaner Disassembly, Cleaning and Reassembly

2.5.1 Disassembly

2.5.2 Cleaning

2.5.3 Reassembly

2.6 Installation

2.7 Intake System Inspection

3. Exhaust System

3.1 Service Standards

3.2 General Description

3.3 Removal

3.4 Inspection

3.5 Installation

3.6 Exhaust System Inspection

4. Turbocharger

4.1 Specifications

4.2 Service Standards

4.2.1 Service Standards Table

4.2.2 Tightening Torque Table

4.2.3 Lubricant Table

4.3 General Description

4.4 Removal

4.5 Disassembly

4.6 Cleaning and Inspection

4.6.1 Cleaning

4.6.2 Inspection

4.7 Reassembly

4.8 Installation

4.9 Post-Installation Inspection

5. Intercooler

5.1 Specifications

5.2 Service Standards

5.3 Outline

5.4 Removal

5.5 Cleaning and Inspection

5.6 Installation

6. Intake Shutter Valve System <Vehicles with Manual Transmission>

6.1 Specifications

6.2 Service Standards

6.2.1 Service Standards Table

6.2.2 Tightening Torque Table

6.3 General Description

6.4 Removal

6.5 Inspection

6.6 Installation

Group 16 – Engine Electrical

Table of Contents

1. Troubleshooting

2. Electrical System

2.1 Specifications

2.2 General Description

2.2.1 Starting System

2.2.2 Charging System

3. Starter

3.1 Service Standards

3.1.1 Service Standards Table

3.1.2 Lubricant

3.2 General Description

3.3 Removal

3.4 Disassembly

3.5 Inspection

3.6 Reassembly

3.7 Testing

3.8 Installation

4. Alternator

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Lubricant Table

4.2 General Description

4.3 Removal

4.4 Disassembly

4.5 Inspection

4.6 Reassembly

4.7 Testing

4.7.1 Handling Precautions

4.7.2 Performance Testing

4.7.3 Regulator Inspection

4.8 Installation

5. Glow System

5.1 Service Standards

5.1.1 Service Standards

5.1.2 Tightening Torque Table

5.1.3 Special Tools Table

5.2 General Description

5.3 Removal

5.4 Inspection

5.4.1 Glow Plug Inspection

5.4.2 Glow Relay Inspection

5.4.3 Glow Controller Inspection

5.5 Installation

Group 21 – Clutch

Table of Contents

1. Troubleshooting

2. Clutch Proper

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.2.3 Special Tools Table

2.3 General Description

2.4 Removal

2.4.1 Operation Before Removal

2.4.2 Removal of Clutch Proper

2.5 Disassembly

2.6 Inspection

2.7 Reassembly

2.8 Installation

2.9 Post-Installation Adjustment

2.10 Lubrication of Drive Pinion Splines

3. Clutch Control

3.1 Specifications

3.2 Service Standards

3.2.1 Service Standards Table

3.2.2 Tightening Torque Table

3.2.3 Sealant Table

3.2.4 Special Tools Table

3.3 General Description

3.4 Clutch Hose and Piping

3.4.1 Removal

3.4.2 Inspection

3.4.3 Installation

3.4.4 Post-Installation Work

3.5 Clutch Pedal Assembly

3.5.1 Removal

3.5.2 Disassembly

3.5.3 Inspection

3.5.4 Reassembly

3.5.5 Installation

3.5.6 Post-Installation Adjustment

3.6 Clutch Master Cylinder

3.6.1 Removal

3.6.2 Disassembly

3.6.3 Inspection

3.6.4 Reassembly

3.6.5 Installation

3.6.6 Post-Installation Adjustment

3.7 Clutch Power Cylinder

3.7.1 Removal

3.7.2 Disassembly

3.7.3 Inspection

3.7.4 Reassembly

3.7.5 Installation

3.7.6 Post-Installation Adjustment

3.8 Clutch Housing Assembly

3.8.1 Removal

3.8.2 Disassembly

3.8.3 Reassembly

3.8.4 Installation

3.8.5 Post-Installation Adjustment

3.9 Fluid Change in the Clutch System

3.10 Bleeding the Clutch System

3.11 Clutch Pedal Inspection and Adjustment

3.12 Clutch Adjustment

Group 22 – Manual Transmission

Table of Contents

1. Troubleshooting

2. Removing and Installing

2.1 Service Standards

2.1.1 Tightening Torque Table

2.2 Preliminary Operations

2.3 Removal

2.4 Installation

3. Transmission Assembly

3.1 Specifications

3.2 Service Standards

3.2.1 Service Standards Table

3.2.2 Tightening Torque Table

3.2.3 Special Tools Table

3.2.4 Sealant Table

3.3 General Description

3.4 Removal

3.4.1 Clutch Housing Assembly

3.4.2 Gear Shift, Upper and Lower

3.4.3 Rear Cover and Parking Brake

3.4.4 Transmission

3.5 Installation

3.5.1 Transmission

3.5.2 Rear Cover

3.5.3 Gear Shift, Upper and Lower

3.5.4 Clutch Housing Assembly

4. Main Shaft Assembly

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Special Tools Table

4.2 Preliminary Inspection

4.3 Disassembly

4.4 Inspection

4.5 Reassembly

5. Counter Shaft Assembly

5.1 Service Standards

5.1.1 Sealant Table

5.2 Special Tools Table

5.3 Disassembly

5.4 Reassembly

6. Reverse Gear

6.1 Service Standards

6.1.1 Service Standards Table

6.1.2 Tightening Torque Table

6.1.3 Special Tools Table

6.2 Disassembly and Inspection

6.3 Reassembly

7. Gear Shift, Lower

7.1 Service Standards

7.1.1 Service Standards Table

7.1.2 Tightening Torque Table

7.1.3 Sealant Table

7.2 General Description

7.3 Disassembly

7.4 Inspection

7.5 Reassembly

8. Gear Shift, Upper

8.1 Service Standards

8.1.1 Service Standards Table

8.1.2 Tightening Torque Table

8.1.3 Sealant Table

8.2 Disassembly

8.3 Inspection

8.4 Reassembly

9. Rear Cover

9.1 Service Standards

9.1.1 Service Standards Table

9.1.2 Tightening Torque Table

9.1.3 Special Tools Table

9.1.4 Sealant Table

9.2 Disassembly

9.3 Inspection

9.4 Reassembly

10. Transmission Control

10.1 Specifications

10.2 Service Standards

10.2.1 Service Standards Table

10.2.2 Tightening Torque Table

10.3 General Description

10.4 Preliminary Operations

10.5 Removal

10.6 Inspection, Repair and Replacement

10.7 Installation

10.8 Control Cable

10.8.1 Shift Cable

10.8.2 Select Cable

10.8.3 Inspection

10.9 Set Board Assembly

10.9.1 Disassembly and Reassembly

Group 23 – Automatic Transmission

Table of Contents

1. Troubleshooting

2. Removing and Installing

2.1 Specifications

2.2 Service Standards

2.2.1 Tightening Torque Table

2.2.2 Special Tools Table

2.3 Removal

2.4 Installation

3. Oil Seal and Speedometer Worm

3.1 Service Standards

3.1.1 Service Standards Table

3.1.2 Tightening Torque Table

3.1.3 Special Tools Table

3.2 Removal and Installation

3.3 Replacement of Front Oil Seal

3.4 Replacement of Rear Oil Seal

3.5 Replacement of Speedometer Worm

4. Automatic Transmission Control System

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Sealant Table

4.2 General Description

4.3 Removal and Installation

4.4 Inspection After Installation

4.5 Oil Cooler

4.6 Fluid Pipe and Oil Temperature Sensor

4.7 Replacement of Fluid and Oil Filter

Group 25 – Propeller Shaft

Table of Contents

1. Troubleshooting

2. Propeller Shaft

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.2.3 Special Tools Table

2.3 General Description

2.4 Removal

2.5 Disassembly

2.6 Inspection

2.7 Reassembly

2.8 Installation

Group 26 – Front Axle

Table of Contents

1. Troubleshooting

2. Front Axle Assembly

2.1 Specifications

2.2 Service Standards

2.2.1 Tightening Torque Table

2.3 General Description

2.4 Removal

2.5 Installation

2.6 Post-Installation Adjustment

3. Wheel Hub and Brake Drum

3.1 Service Standards

3.1.1 Service Standards Table

3.1.2 Tightening Torque Table

3.1.3 Sealant Table

3.1.4 Special Tools Table

3.2 Disassembly

3.3 Inspection

3.4 Reassembly

4. Front Axle and Knuckle

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Special Tools Table

4.2 Removal

4.3 Disassembly

4.4 Inspection

4.5 Reassembly

4.6 Installation

Group 27 – Rear Axle

Table of Contents

1. Troubleshooting

2. Rear Axle Assembly

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.2.3 Special Tools Table

2.3 General Description

2.4 Removal

2.5 Inspection

2.6 Installation

3. Wheel Hub and Brake Drums

3.1 Service Standards

3.1.1 Service Standards Table

3.1.2 Tightening Torque Table

3.1.3 Special Tools Table

3.2 Disassembly

3.3 Inspection

3.4 Reassembly

4. Reduction and Differential

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Lubricant Table

4.1.4 Special Tools Table

4.2 Removal

4.3 Pre-Disassembly Inspection

4.4 Disassembly

4.5 Inspection

4.6 Reassembly

4.7 Installation

Group 31 – Wheels and Tires

Table of Contents

1. Troubleshooting

2. Wheel and Tire

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.3 General Description

2.4 Removal

2.4.1 Preparation for Removal

2.4.2 Removing Front Tires

2.4.3 Removing Rear Tires

2.5 Removal of Tire

2.6 Inspection

2.7 Installation of Tire

2.8 Inspection and Adjustment After Installation

2.9 Installation

Group 33 – Front Suspension

Table of Contents

1. Troubleshooting

2. Front Suspension Assembly

2.1 Service Standards

2.1.1 Service Standards Table

2.1.2 Tightening Torque Table

2.1.3 Special Tools Table

2.2 General Description

2.3 Removal

2.4 Inspection

2.5 Installation

3. Leaf Springs

3.1 Specifications

3.2 Service Standards

3.3 General Description

3.4 Pre-Disassembly Inspection

3.5 Disassembly

3.6 Inspection

3.7 Reassembly

4. Shock Absorbers

4.1 Specifications

4.2 General Description

4.3 Disassembly

4.4 Inspection

5. Stabilizer

5.1 General Description

5.2 Pre-Disassembly Inspection

5.3 Disassembly

5.4 Inspection

5.5 Reassembly

Group 34 – Rear Suspension

Table of Contents

1. Troubleshooting

2. Rear Suspension Assembly

2.1 Service Standards

2.1.1 Service Standards Table

2.1.2 Tightening Torque Table

2.1.3 Special Tools Table

2.2 General Description

2.3 Removal

2.4 Inspection

2.5 Installation

3. Leaf Springs

3.1 Specifications

3.2 General Description

3.3 Pre-Disassembly Inspection

3.4 Disassembly

3.5 Inspection

3.6 Reassembly

4. Shock Absorbers

4.1 Specifications

4.2 General Description

4.3 Disassembly

4.4 Inspection

5. Stabilizer

5.1 General Description

5.2 Pre-Disassembly Inspection

5.3 Disassembly

5.4 Inspection

5.5 Reassembly

Group 35 – Brake

Table of Contents

1. Troubleshooting

2. Brake System

2.1 Specifications

2.2 Service Standards

2.2.1 Tightening Torque Table

2.2.2 Special Tools Table

2.3 General Description

2.4 Bleeding the Brake Fluid Lines

2.5 Changing the Brake Fluid

3. Brake Piping and Brake Fluid Tank

3.1 Service Standards

3.1.1 Tightening Torque Table

3.2 General Description

3.3 Inspection Before Removal

3.4 Removing the Brake Fluid

3.5 Removal

3.6 Disassembly

3.7 Inspection

3.8 Reassembly

3.9 Installation

4. Air Tank

4.1 Specifications

4.2 Service Standards

4.2.1 Service Standards Table

4.2.2 Tightening Torque Table

4.2.3 Sealant Table

4.3 General Description

4.4 Drain Cock

4.4.1 Air Leak Test

4.4.2 Functional Inspection

4.4.3 Removal

4.4.4 Installation

4.5 Safety Valve

4.5.1 Air Leak Test

4.5.2 Functional Inspection

4.5.3 Removal

4.5.4 Installation

4.6 Air Tank

4.6.1 Air Leak Test

4.6.2 Removal

4.6.3 Installation

5. Air Compressor

5.1 Specifications

5.2 Service Standards

5.2.1 Service Standards Table

5.2.2 Tightening Torque Table

5.2.3 Special Tools Table

5.3 General Description

5.4 Removal

5.5 Disassembly

5.6 Inspection

5.7 Reassembly

5.8 Installation

6. Brake Pedal Assembly

6.1 Service Standards

6.1.1 Service Standards Table

6.1.2 Tightening Torque Table

6.2 Removal

6.3 Disassembly

6.4 Inspection

6.5 Reassembly

6.6 Installation

6.7 Adjusting the Pedal Height

7. Dual Brake Valve

7.1 Specifications

7.2 Service Standards

7.2.1 Service Standards Table

7.2.2 Tightening Torque Table

7.2.3 Sealant Table

7.3 General Description

7.4 Removal

7.5 Disassembly

7.6 Inspection

7.7 Reassembly

7.8 Installation

8. Brake Booster (Air-Master)

8.1 Specifications

8.2 Service Standards

8.2.1 Service Standards Table

8.2.2 Tightening Torque Table

8.2.3 Sealant Table

8.3 General Description

8.4 Removal

8.5 Disassembly

8.6 Inspection

8.7 Reassembly

8.8 Installation

8.9 Inspection After Installation

9. Air Dryer

9.1 Specifications

9.2 Service Standards

9.2.1 Service Standards Table

9.2.2 Tightening Torque Table

9.2.3 Sealant Table

9.3 General Description

9.4 Maintenance and Inspection

9.4.1 Maintenance and Inspection

9.4.2 Inspection and Replacement of Desiccant

9.4.3 Inspection After Replacement

9.5 Removal

9.6 Disassembly

9.7 Reassembly

9.8 Inspection After Reassembly

9.9 Installation

9.10 Inspection After Installation

10. Air Pressure Governor

10.1 Specifications

10.2 Service Standards

10.2.1 Service Standards Table

10.2.2 Tightening Torque Table

10.2.3 Sealant Table

10.3 General Description

10.4 Functional Inspection

10.5 Adjustment

10.6 Removal

10.7 Disassembly

10.8 Reassembly

10.9 Installation

11. Check Valve

11.1 Service Standards

11.1.1 Service Standards Table

11.1.2 Tightening Torque Table

11.1.3 Sealant Table

11.2 General Description

11.3 Removal

11.4 Disassembly

11.5 Inspection

11.6 Reassembly

11.7 Installation

12. Switch

12.1 Specifications

12.2 Service Standards

12.2.1 Tightening Torque Table

12.2.2 Sealant Table

12.3 Stop Lamp Switch

12.3.1 Removal

12.3.2 Inspection

12.3.3 Installation

12.4 Low Air Pressure Switch

12.4.1 Removal

12.4.2 Inspection

12.4.3 Installation

13. Front Drum Brake

13.1 Specifications

13.2 Service Standards

13.2.1 Service Standards Table

13.2.2 Tightening Torque Table

13.2.3 Special Tools Table

13.3 General Description

13.4 Removal

13.5 Disassembly

13.6 Inspection

13.7 Reassembly

13.8 Wheel Cylinder

13.8.1 Disassembly

13.8.2 Inspection

13.8.3 Reassembly

13.9 Installation

13.10 Adjusting Holder Pin

13.11 Adjusting Shoe Clearance

14. Rear Drum Brake

14.1 Specifications

14.2 Service Standards

14.2.1 Service Standards Table

14.2.2 Tightening Torque Table

14.2.3 Special Tools Table

14.3 General Description

14.4 Removal

14.5 Disassembly

14.6 Inspection

14.7 Reassembly

14.8 Wheel Cylinder

14.8.1 Disassembly

14.8.2 Inspection

14.8.3 Reassembly

14.9 Installation

14.10 Adjusting Holder Pin

14.11 Adjusting Shoe Clearance

15. Exhaust Brake System

15.1 Specifications

15.2 Service Standards

15.2.1 Service Standards Table

15.2.2 Tightening Torque Table

15.2.3 Sealant Table

15.3 General Description

15.4 Removal

15.5 Disassembly

15.5.1 Exhaust Brake Unit

15.6 Inspection

15.7 Reassembly

15.8 Installation

15.9 Operation Test After Installing

15.10 Control Cylinder

15.10.1 Disassembly

15.10.2 Inspection

15.10.3 Reassembly

15.10.4 Inspection After Assembly

15.11 Supply Valve

15.11.1 Disassembly

15.11.2 Reassembly

15.11.3 Airtightness Test After Reassembling

15.11.4 Operation Test After Reassembling

Group 36 – Parking Brake

Table of Contents

1. Troubleshooting

2. Parking Brake Control

2.1 Specifications

2.2 Service Standards

2.2.1 Service Standards Table

2.2.2 Tightening Torque Table

2.3 General Description

2.4 Removal

2.4.1 Preliminary Operation

2.4.2 Parking Brake Cable

2.4.3 Parking Brake Lever Assembly

2.5 Disassembly and Inspection

2.5.1 Disassembly

2.5.2 Inspection

2.6 Reassembly

2.7 Installation

2.7.1 Parking Brake Lever Assembly

2.7.2 Parking Brake Cable

2.8 Post-Installation Adjustment

3. Parking Brake Drum and Shoes

3.1 Specifications

3.2 Service Standards

3.2.1 Service Standards Table

3.2.2 Tightening Torque Table

3.2.3 Special Tools Table

3.3 General Description

3.4 Removal

3.4.1 Preliminary Operation

3.4.2 Removal

3.5 Disassembly and Inspection

3.5.1 Disassembly

3.5.2 Inspection

3.6 Reassembly

3.7 Installation

Group 37 – Steering

Table of Contents

1. Troubleshooting

2. Power Steering System

2.1 Service Standards

2.1.1 Service Standards Table

2.1.2 Tightening Torque Table

2.2 General Description

2.3 Replacement of Power Steering Fluid

2.4 Performance Verification Tests

2.5 Overall Checks on Power Steering

3. Steering Wheel and Shaft

3.1 Specifications

3.2 Service Standards

3.2.1 Tightening Torque Table

3.3 General

3.4 Removal

3.5 Disassembly

3.6 Reassembly

3.7 Installation

3.8 Inspection After Installation

4. Steering Linkage

4.1 Service Standards

4.1.1 Service Standards Table

4.1.2 Tightening Torque Table

4.1.3 Special Tools Table

4.2 General Description

4.3 Drag Link

4.3.1 Removal

4.3.2 Disassembly

4.3.3 Inspection and Reassembly

4.3.4 Installation

4.4 Tie Rod

4.4.1 Removal

4.4.2 Disassembly

4.4.3 Inspection and Reassembly

4.4.4 Installation

4.5 Post-Installation Inspection and Adjustment

5. Power Steering Booster

5.1 Specifications

5.2 Service Standards

5.2.1 Service Standards Table

5.2.2 Tightening Torque Table

5.2.3 Sealant Table

5.2.4 Special Tools Table

5.3 General Description

5.3.1 Construction

5.3.2 Operation

5.4 Removal

5.5 Disassembly

5.6 Inspection

5.7 Reassembly

5.8 Installation

5.9 Post-Installation Work

6. Power Steering Oil Pump

6.1 Specifications

6.2 Service Standards

6.2.1 Service Standards Table

6.2.2 Tightening Torque Table

6.2.3 Special Tools Table

6.3 General Description

6.4 Removal

6.5 Disassembly

6.6 Inspection

6.7 Reassembly

6.8 Installation

6.9 Post-Installation Inspection and Adjustment

Group 41 – Frame

Table of Contents

1. Frame Assembly

1.1 Specifications

1.2 General Description

1.3 Inspection and Repair

1.3.1 Frame

1.3.2 Rivets

1.4 Frame Shape

Group 42 – Cab

Table of Contents

1. Troubleshooting

2. Cab Proper

2.1 Specifications

2.2 Service Standards

2.3 General Description

2.4 Tilting the Cab

2.5 Removal

2.5.1 Operation Before Removal

2.5.2 Operation in the Cab

2.5.3 Operation at the Cab Front

2.5.4 Operation with the Cab Tilted

2.5.5 Hoisting the Cab

2.6 Installation

2.6.1 Installing the Cab

2.6.2 Operation with the Cab Tilted

2.6.3 Operation from Front of the Cab

2.6.4 Operation in the Cab

2.6.5 Post-Installation Operation

3. Cab Mounting

3.1 Specifications

3.2 Service Standards

3.3 General Description

3.3.1 Cab Mounting

3.3.2 Cab Hinge

3.3.3 Cab Stay

3.3.4 Cab Tilt Link

3.4 Cab Tilt Link

3.4.1 Removal

3.4.2 Installation

3.4.3 Inspection and Adjustment After Installation

3.5 Rear Cab Mounting

3.5.1 Removal

3.5.2 Installation

3.5.3 Post-Installation Inspection and Adjustment

3.6 Cab Hinge

3.6.1 Removal

3.6.2 Installation

3.6.3 Post-Installation Operation

4. Front Windshield Glass and Rear Window Glass

4.1 Specifications

4.2 Service Standards

4.3 Removal

4.3.1 Operation Before Removal

4.3.2 Removal

4.4 Installation

4.4.1 Installation Operation

4.4.2 Post-Installation Operation

5. Door Assembly

5.1 Specifications

5.2 Service Standards

5.3 General Description

5.4 Removal

5.4.1 Removing the Door Trim

5.4.2 Removing the Front Door Window Regulator

5.4.3 Removing the Front Door Locking System

5.4.4 Removing the Outside Mirror Stay Assembly

5.4.5 Removing the Front Door Panel Assembly

5.5 Installation

5.5.1 Installing the Front Door Panel Assembly

5.5.2 Installing the Outside Mirror Stay Assembly

5.5.3 Installing the Front Door Locking System

5.5.4 Inspection and Adjustment After Installation of the Front Door Locking System

5.5.5 Installing the Front Door Window Regulator

5.5.6 Installing the Door Trims

6. Seats, Seat Belts and Floor Mat

6.1 Specifications

6.2 Service Standards

6.3 Removal

6.3.1 Removing the Seats

6.3.2 Removing the Seat Belts

6.3.3 Removing the Floor Mats

6.4 Installation

6.4.1 Installing the Floor Mats

6.4.2 Installing the Seat Belts

6.4.3 Installing the Seats

7. Trim

7.1 Specifications

7.2 Removal

7.3 Installation

8. Instrument Panel

8.1 Service Standards

8.2 Removal

8.3 Installation

8.4 Post-Installation Operation

9. Wiper and Washer

9.1 Service Standards

9.2 Removal

9.3 Installation

9.4 Post-Installation Inspection

10. Cab and Associated Parts

10.1 Service Standards

10.2 Removal

10.3 Installation

10.4 Post-Installation Inspection

11. Silencer and Enclosure

11.1 Removal

11.2 Installation

Group 54 – Chassis Electrical

Table of Contents

1. Troubleshooting

2. Chassis Electrical

2.1 Specifications

2.2 General Description

2.3 Wiring Harness

2.4 Centralized Ground Connections

3. Battery

3.1 Specifications

3.2 Service Standards

3.3 General Description

3.4 Removal

3.5 Inspection

3.6 Installation

4. Fuses and Relays

4.1 Specifications

4.2 Service Standards

4.3 General Description

4.4 Removal and Installation

4.5 Inspection

4.5.1 Fuses

4.5.2 Relays

5. Fusible Link

5.1 Specifications

5.2 General Description

5.3 Removal and Inspection

5.4 Installation

6. Starter Switch and Cold Start Switch

6.1 Specifications

6.2 General Description

6.3 Removal and Installation

6.4 Inspection

7. Steering Column Switches

7.1 Specifications

7.2 General Description

7.3 Inspection

8. Lighting System

8.1 Specifications

8.2 Service Standards

8.3 General Description

8.3.1 Lamps and Switches

8.3.2 Circuit Description

8.4 Removal

8.5 Inspection

8.6 Installation

8.7 Inspection and Adjustment After Installation

9. Meters and Gauges

9.1 Specifications

9.2 Service Standards

9.3 General Description

9.4 Removal

9.5 Inspection

9.6 Installation

9.7 Inspection After Installation

10. Indicator and Warning Lamp System

10.1 Specifications

10.2 Service Standards

10.3 General Description

10.3.1 Function of Each Lamp

10.3.2 Operation of Each Lamp

10.4 Removal and Installation

10.5 Inspection

11. Exhaust Brake System (Vehicles with Manual Transmission)

11.1 Specifications

11.2 Service Standards

11.3 General Description

11.4 Removal and Installation

11.5 Inspection

11.6 Inspection After Installation

12. Wiper and Washer System

12.1 Specifications

12.2 Service Standards

12.3 General Description

12.3.1 Wiper System

12.3.2 Washer System

12.4 Removal and Installation

12.5 Inspection and Cleaning

12.6 Inspection and Adjustment After Installation

13. Substarter System

13.1 General Description

13.2 Removal and Installation

13.3 Inspection

14. Horn

14.1 Specifications

14.2 General Description

14.3 Removal and Installation

14.4 Inspection

14.5 Inspection After Installation

15. Radio (Option), Cassette Stereo (Option), Speakers, and Antenna

15.1 Specifications

15.2 General Description

15.3 Removal and Installation

15.4 Inspection and Adjustment

16. Cigarette Lighter

16.1 Specifications

16.2 Service Standards

16.3 General Description

16.4 Removal and Installation

16.5 Inspection

16.6 Inspection After Installation

Group 55A – Air Conditioner

Group 55A (9402) – Air Conditioner

Table of Contents

1. Specifications

2. Outlines of Refrigeration System

2.1 Air System

2.2 Refrigerating Cycle

2.3 Electrical System

3. Construction

3.1 Engine Compartment

3.2 Cab

3.3 Control System

3.4 Compressor and Magnetic Clutch

3.4.1 Compressor

3.4.2 Check Valve

3.4.3 Magnetic Clutch

3.5 Condenser

3.6 Receiver Drier

3.7 Cooling Unit

3.8 Expansion Valve

3.9 High Pressure Switch

3.10 Power Relay

3.11 A/C Switch

3.12 Thermo Sensor

4. Troubleshooting

4.1 General Precautions

4.2 Trouble, Cause and Remedy

4.3 Inspection Procedures

4.3.1 A/C Switch

4.3.2 High Pressure Switch

4.3.3 Thermo Sensor

4.3.4 Magnetic Clutch

4.3.5 Refrigerant Charge

4.3.6 Receiver Drier Assembly

4.3.7 Belt Tension

4.3.8 Expansion Valve

4.3.9 Compressor

4.3.10 Air Inclusion in Refrigerant Circuit

4.3.11 Moisture Inclusion in Refrigerant Circuit

5. Removal and Installation

5.1 Precaution for Removal and Installation

5.2 Removal

5.2.1 Inside the Engine Compartment

5.2.2 Inside the Cab

5.3 Installation

6. Treatment After Installation

6.1 Check and Adjustment

6.2 Refrigerant Charge

6.2.1 Installation of Charge Equipment

6.2.2 Refrigerant Charge and Leak Check

6.2.3 Removal of Charge Equipment

6.3 Gas Charge

6.4 Checking the Refrigerant Level

6.5 Performance Test

6.5.1 Preparation

6.5.2 Stationary Performance Test

7. Cooling Unit

7.1 Components

7.2 Cautions in Disassembling

7.3 Disassembling

8. Maintenance

9. Compressor

9.1 Disassembling the Clutch

9.2 Reassembly the Clutch

9.3 Disassembling the Shaft Seal

9.4 Reassembly the Shaft Seal

9.5 Special Tool Figure

Group 55A (9106) – Air Conditioner

Table of Contents

1. Specifications

2. Outlines of Refrigeration System

2.1 Air System

2.2 Refrigerating Cycle

2.3 Electrical System

3. Construction

3.1 Engine Compartment

3.2 Cab

3.3 Control System

3.4 Compressor and Magnetic Clutch

3.4.1 Compressor

3.4.2 Check Valve

3.4.3 Magnetic Clutch

3.5 Condenser

3.6 Receiver Drier

3.7 Cooling Unit

3.8 Expansion Valve

3.9 High Pressure Switch

3.10 Power Relay

3.11 A/C Switch

3.12 Thermo Sensor

4. Troubleshooting

4.1 General Precautions

4.2 Trouble, Cause and Remedy

4.3 Inspection Procedures

4.3.1 A/C Switch

4.3.2 High Pressure Switch

4.3.3 Thermo Sensor

4.3.4 Magnetic Clutch

4.3.5 Refrigerant Charge

4.3.6 Receiver Drier Assembly

4.3.7 Belt Tension

4.3.8 Expansion Valve

4.3.9 Compressor

4.3.10 Air Inclusion in Refrigerant Circuit

4.3.11 Moisture Inclusion in Refrigerant Circuit

5. Removal and Installation

5.1 Precaution for Removal and Installation

5.2 Removal

5.2.1 Inside the Engine Compartment

5.2.2 Inside the Cab

5.3 Installation

6. Treatment After Installation

6.1 Check and Adjustment

6.2 Refrigerant Charge and Leak Check

6.2.1 Installation of Charge Equipment

6.2.2 Refrigerant Charge and Leak Check

6.2.3 Removal of Charge Equipment

6.3 Gas Charge

6.4 Checking the Refrigerant Level

6.5 Performance Test

6.5.1 Preparation

6.5.2 Stationary Performance Test

7. Cooling Unit

7.1 Components

7.2 Cautions in Disassembling

7.3 Disassembling

8. Maintenance

9. Compressor

9.1 Disassembling the Clutch

9.2 Reassembly the Clutch

9.3 Disassembling the Shaft Seal

9.4 Reassembly the Shaft Seal

9.5 Special Tool Figure

Group 55B – Heater

Table of Contents

1. Troubleshooting

2. Heater and Ventilation

2.1 Specifications

2.2 Service Standards

2.3 General Descriptions

2.4 Wiring Diagram

2.5 Pre-Removal Inspection

2.5.1 Blower Switch Inspection

2.5.2 Mode Control Lever Inspection

2.5.3 Temperature Control Lever Inspection

2.5.4 Air Selector Lever Inspection

2.5.5 Side Ventilator Inspection

2.6 Removal

2.7 Installation

2.8 Post-Installation Adjustments

3. Heater Plumbing

3.1 Removal

3.2 Inspection

3.3 Installation