Covers: 1992, 1993, 1994, 1995 Mitsubishi FUSO FK FM Series Trucks

- FK417 w/ 6D14-T4

- FK457 w/ 6D14-T4

- FM457 w/ 6D14-T4

- FM557 w/ 6D14-T2 or 6D14-T4

Region: North America

Complete service manual with over 1,200 pages. This manual generally covers OEM service, repair and troubleshooting procedures used by professional truck techs. Detailed illustrations, specifications, diagrams and other useful information are included to safely and correctly perform the job at hand.

A PDF format manual will be delivered to your PC, Mac, tablet or smartphone. The manual is fully searchable, printable and has a bookmarks panel to make finding content easy.

Includes:

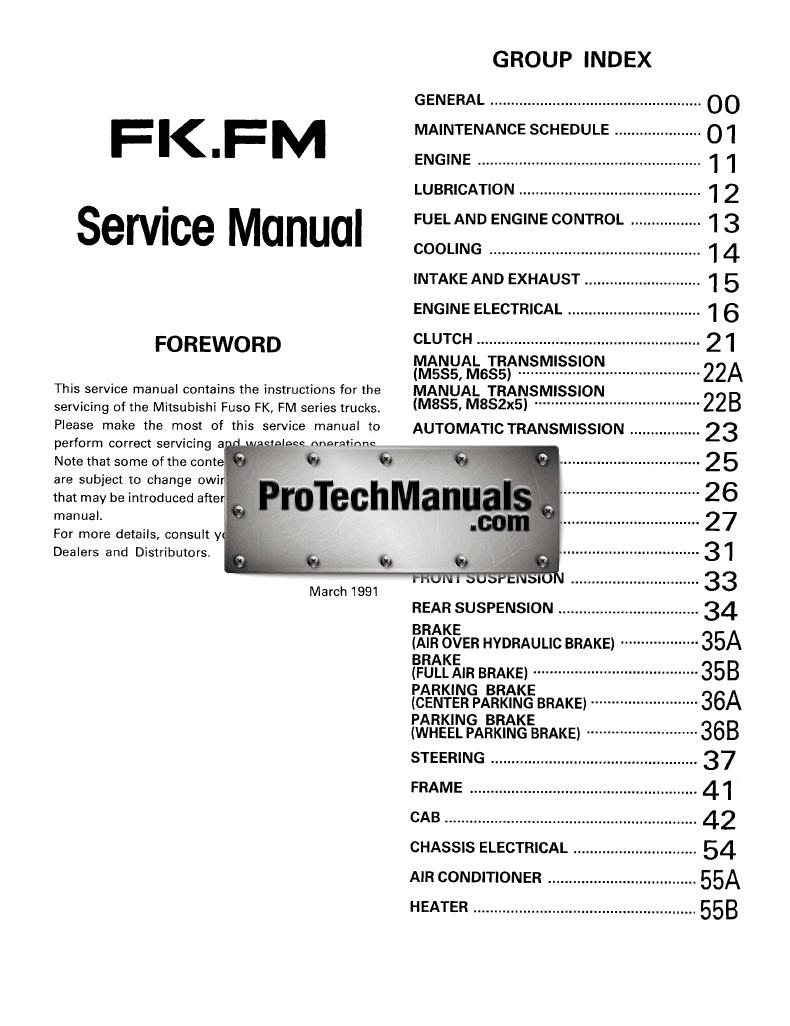

- 1992-1995 FUSO FK, FM Service Manual — TWME9107 plus model year changes

Digital download only.

Contents:

- General Information

- Identification

- Specifications

- 1993 Changes

- 1994 Changes

- 1995 Changes

- Maintenance Schedule and Procedures

- Engine Removal and Installation

- Engine Service and Overhaul

- Lubrication System

- Fuel System and Engine Control

- Cooling System

- Intake and Exhaust

- Turbocharger

- Starter, Alternator and Glow System

- Clutch and Clutch Pedal

- Flywheel

- Manual Transmission (M5S5, M6S5, M8S5, M8S2x5, M6S6)

- Automatic Transmission (R&I only – refer to Allison for service)

- Driveshaft

- Axles and Hubs

- Differential

- Brakes

- Parking Brake

- Wheels and Tires

- Front and Rear Suspension

- Steering

- Frame Inspection

- Cab and Interior

- Chassis Electrical Components

- Air Conditioning System

- Heater

File details:

- Pages: 1,252

- Format: PDF

- File size: 50mb

- Features: Bookmarks, searchable, printable

- Compatible with: PC/Mac/smartphone/tablet